Cardboard might seem harmless, but to the container shipping industry, it’s a mountain of waste waiting to happen. Cardboard balers are stepping up to be unsung heroes, helping ports, warehouses and logistics hubs manage waste smarter, cheaper and cleaner.

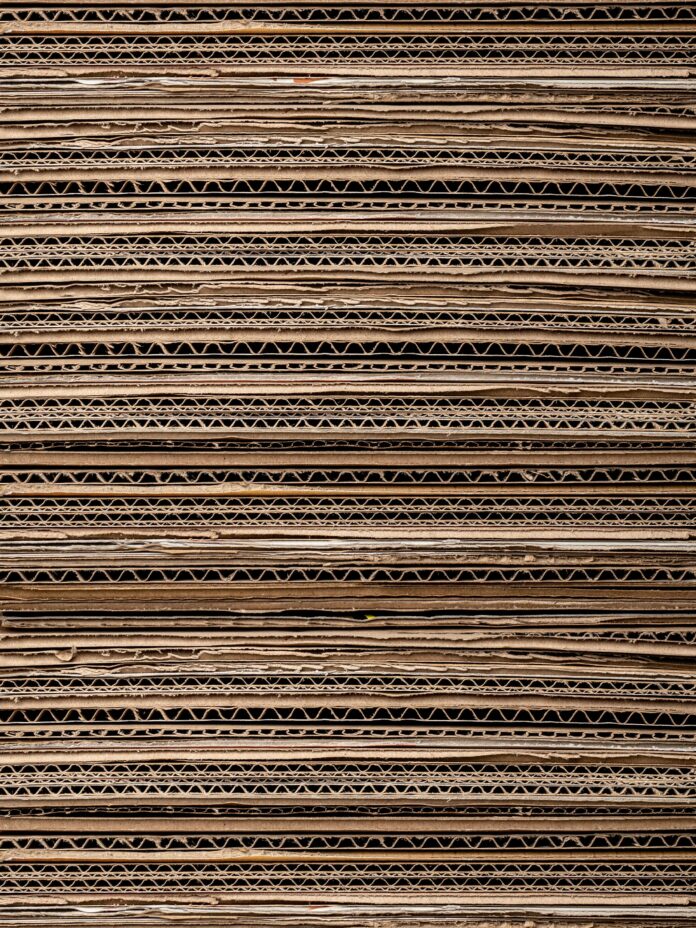

Walk into any major shipping terminal or distribution center, and it’s a common sight: Tall piles of used boxes, flattened cartons and bulky pieces of packaging materials. Cardboard waste has quietly become a major problem in the shipping industry amidst the explosive growth of e-commerce and global trade.

Ports, freight companies and logistics facilities in every shape and size process thousands of tons of cardboard every month. From packaging goods for long-distance transport to repacking items for distribution, cardboard is everywhere. The problem? It takes up massive amounts of space, it’s costly to dispose of and it’s not exactly great for the environment if left unmanaged.

That’s where cardboard balers come in: Machines designed to compress and bundle cardboard waste into compact, manageable bales. To companies involved in shipping and logistics, these balers are fast becoming an indispensable tool for keeping operations clean and efficient.

What exactly is a cardboard baler?

A cardboard baler can be thought of as a kind of mechanical solution to waste. Used boxes, instead of piling up, are squeezed into compact blocks that are uniform in size. Such bales are easy to handle and store and, above all, can be directly sent for recycling.

They come in a few different forms. For smaller facilities where floor space is at a premium, vertical balers are popular. Large operations that handle high volumes of cardboard use horizontal balers. Automated systems can also tie and eject the bales with very little human input to keep a smooth and safe workflow.

For container shipping firms, where space is money and downtime is the enemy, this sort of automation is more than a luxury, it’s a necessity.

Bramidan USA is powering a smarter, greener future

When it comes to a cardboard baler for sale, one name keeps coming to the front: Bramidan USA. Known for their innovative recycling and waste management solutions, Bramidan designs top-quality balers and compactors for all types of industries-from retail and manufacturing to, of course, logistics and shipping.

What separates Bramidan from others is not just the machinery but their approach toward sustainability and efficiency: Long-lasting, easy-to-use machines and units are customized to meet specific business needs. Whether it is a compact vertical baler or a fully automated horizontal system that the facility requires, Bramidan’s range has something that will fit.

The company website emphasizes that proper waste handling is not just a question of saving money, but about creating cleaner and safer workplaces and also taking care of the planet. And the testimonials prove this: Customers speak of how Bramidan balers have simplified their operations and minimized their waste without overcomplicating daily routines. For a shipping industry where time is of the essence, that is a pretty big deal.

Why cardboard balers matter in the shipping world

Let’s face it: Cardboard waste might not sound glamorous, but handling it efficiently does make a serious difference to the bottom line of a company and to its environmental footprint. Here’s why:

Space saving

Loose cardboard takes up a ridiculous amount of space in warehouses, trucks and ports. Compressing it into bales frees the company’s valuable square footage for bigger and better things, such as cargo storage and smooth operations.

Cost reduction

Waste disposal is usually based on volume, so the fewer pickups and smaller the loads, the lower the overall costs will be. In fact, many recycling facilities pay for neatly baled cardboard, and what once was considered trash turns into a small but steady revenue stream.

Environmental impact

Shipping companies now face greater pressure to reduce their carbon footprint. Cardboard balers help this by making recycling easier and efficient, reducing landfill waste and supporting sustainable business practices-something increasingly important to customers.

Safer workspaces

Stacks of loose boxes can even present a safety hazard. Balers help keep work areas tidier and more organized to avoid accidents and keep compliance with laws and regulations about safety.

Making cardboard management a strategic advantage

While the margins are thin in many aspects of the business, and environmental scrutiny mounts, every little bit counts. Cardboard balers aren’t just a piece of equipment but a long-term investment in operational efficiency. Onsite baling systems can help facilities minimize their downtime, cut hauling costs and improve their rates of recycling.

This is a win-win for the business and the planet. And not to mention the optics: Sustainability matters more than ever. Those ports and shipping companies taking steps to demonstrably reduce waste and lean into greener practices gain an edge of reputation with clients and regulators alike.

The bottom line

Cardboard might be a small component of the big container shipping puzzle, but handling it efficiently can make quite a difference. From cleaner work environments, to lower operating costs and greener operations, cardboard balers are proving to be indispensable in modern logistics. As international trade continues to expand, so does the need for smart, sustainable waste solutions.

Companies such as Bramidan USA lead the charge, offering reliable equipment that keeps businesses ahead: Efficient, compliant and environmentally responsible. So, the next time you see those towering stacks of boxes waiting to be shipped or discarded, just know that behind every clean, organized facility, there’s probably a hardworking baler keeping chaos in check.