PepsiCo Polska will launch a new automated warehouse in Grodzisk Mazowiecki in the third quarter of 2026. The facility will use Mecalux technology to connect production and dispatch operations, increasing logistics capacity and reducing CO₂ emissions.

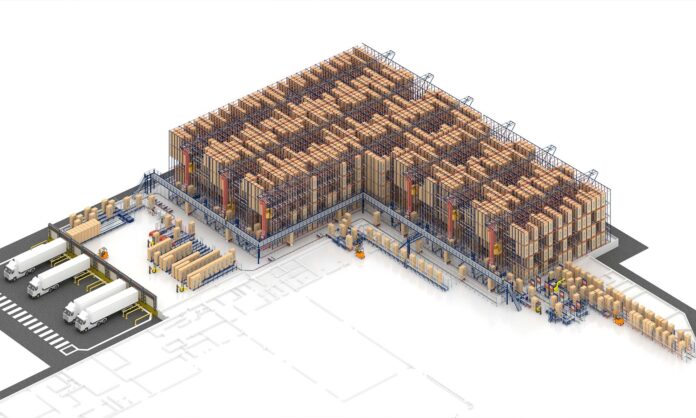

The automated storage and retrieval system (AS/RS) will handle potato crisps and other snacks. It was designed to boost efficiency without expanding the existing building. The system will operate 24/7 to support continuous production.

The project includes six stacker cranes and racking with an Automated Pallet Shuttle. A floor-mounted electric monorail and automatic conveyors will connect the warehouse directly to production lines, ensuring a steady pallet flow.

Mecalux’s Easy WMS warehouse management system will oversee operations. Integrated with PepsiCo’s SAP eWM software, it will synchronize all logistics processes, from goods receipt to outbound shipments.

“With this project, we’re linking production, storage, and dispatch through automation,” said Bartłomiej Lesiuk, Warehouse Automation Design Manager at PepsiCo. “The modular design allows us to adapt to future needs.”

This is PepsiCo Polska’s third warehouse project with Mecalux. The Grodzisk Mazowiecki site features advanced technology, including energy recovery systems that cut power use by up to 20%. AI-powered computer vision ensures safe and precise pallet placement.

“With this investment, we’ll optimise operations, expand capacity, and reduce costs,” added Lesiuk. “Automation will enable direct deliveries, eliminating double handling and unnecessary transport. We also expect to cut greenhouse gas emissions by 200 tonnes annually.”