In this exclusive interview, Container News Managing Editor Antonis Karamalegkos speaks with Harrison Nguyen, Business Development Manager at Realtime Business Solutions (RBS). Harrison Nguyen shares his insights about terminal operations systems evolution, and how RBS new product contribute to terminal operation improvements.

Would you like to introduce yourself and RBS to our readers?

My name is Harrison Nguyen. I’ve been working with RBS for about five years. RBS is a terminal operating system (TOS) provider. More widely speaking, RBS is a software provider for all different types of terminals and we provide software that helps manage and optimize an overall terminal’s operations.

My personal background is in Computer Science. I spent time in the software development team, creating and programming the software. And then about two years ago, I transitioned over to the client-facing side and now I look after all the business development in the company.

How have TOS evolved in recent years and how new technologies and digital systems have contributed to the change?

I think when TOS was originally founded probably about 50 years ago, it was very much designed as a basic tool to help people operate the terminal and keep track of the terminal better. But in more recent years, it’s evolved into being a higher-level kind of system that can do things automatically and with a lot more intelligence.

There are some trends around that have supported such a development. Number one would be the increase in automation. With better software and better equipment, there has been an increase in overall automation, both at a process level and at a physical level. And that has been a core part of the TOS and how that’s evolved.

Number two, there have been a lot of new technologies in terms of hosting. Nowadays, we see a lot of cloud implementations, meaning any type of implementation where the server sits virtually off-site, and not on a local on-prem server, which has led to many different methods of implementation and increased flexibility around TOS usage and overall importance.

Another important one kind of linking to both of those would be Internet of Things (IoT). Now, with better hardware, there’s a lot of integration between all these different sensors, equipment, and technologies creating a more complete and comprehensive picture for better terminal operations.

A recent trend is optimization layer. With the complexities that a terminal experiences today, it becomes very difficult for humans to manage this massive influx of data and decision-making. Therefore, there is now increased interest in optimization layers and intelligent features that can make these decisions for the terminals and the terminal planners.

That’s where we really see some of the core trends and changes over the last 10 to 15 years that will continue to influence the industry greatly.

Can we mention the inability for a container terminal to operate without a TOS as the main difference compared to the past?

Yes, I think that’s completely true. I believe that as container volumes have grown, meaning that more boxes have been shipped around, it just becomes almost impossible to operate a terminal efficiently without a well-working TOS.

Especially, I would say, that any terminal handling more than 200,000-300,000 TEUs per year, is impossible to operate without a TOS.

What are the new challenges arising from the new technologies in the TOS sector?

There are many different challenges in our sector. Cybersecurity is one of the main points. With all the automation process and the new intelligent features, there is now a heavier reliance on the systems. And because of that, the digital systems become the focus of a lot of attacks.

Additionally, nowadays there are more aspects/parts of a TOS, because the systems have become more complexed, so it requires a bigger job from the vendors to make sure every part of the system is secure.

The last part would be the IoT, regarding the connection and integration of all these systems with other different systems and technologies. There may be exposed endpoints and exposed areas that could lead to potential risks.

That goes together with the complexity, but overall, it’s about how do the vendors manage and understand all these points to make sure that the system is secure and that the terminal is secure.

Do you see any increased demand in the TOS market during crisis periods, such as Covid-19 pandemic, Red Sea crisis, Ukraine war, among others?

Overall, in terms of the global market for terminal operating systems, and logistics in general, even during crisis periods, we don’t see a massive change in overall demand. However, I will say that there are geographical changes. In cases such as the Ukraine war or the Red Sea crisis, there have been geographical changes in demand because of the changes in specific regions.

During the Red Sea crisis, for instance, the Red Sea area was obviously impacted heavily. However, as the vessels started to around the Cape of Good Hoep in Africa, we saw increased demand in the African region.

So, you can say that geographically the cargo traffic shifted from the Red Sea area down to Africa, but overall, logistics and global trade have maintained a very strong demand.

With the whole cloud-based and system automations, I think there has also now been an understanding that TOS is a very essential thing to all terminals. And so that’s why it hasn’t really been affected by global crises.

Is there a different approach by RBS about the integrating process on an established container terminal, compared to a smaller one?

Yes, a slightly different approach because at the end of the day, a lot of it comes down to the experience of the terminal and what they’ve been able to achieve before.

In an established terminal, the level of understanding and sophistication is already there. You can delve into deeper topics and more intelligent topics in terms of the system, not in terms of the functions, but more in terms of the actual intelligent features in the system.

In a greenfield terminal, there’s definitely a more education approach where you have to guide them through some steps and help them to understand certain things, before we get to the higher end features about automation and stuff like that.

Overall, we follow a process that is about collaboration and partnership, but the stages and the type of information we convey is always dependent on the characteristics of each terminal.

What is your latest product and how does this product use new technologies to improve terminal operations?

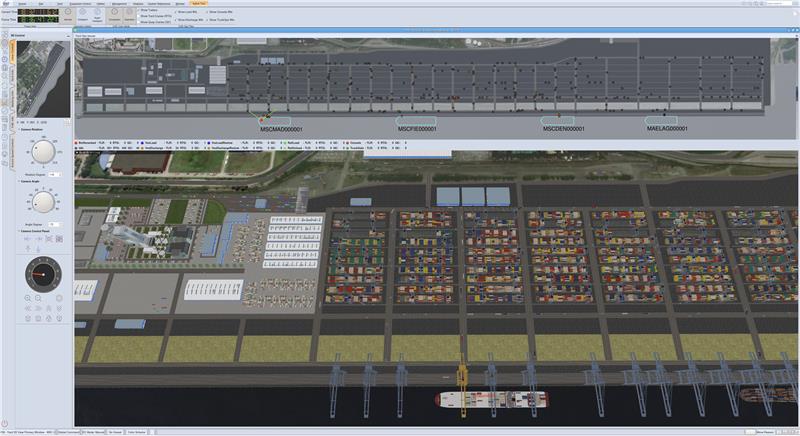

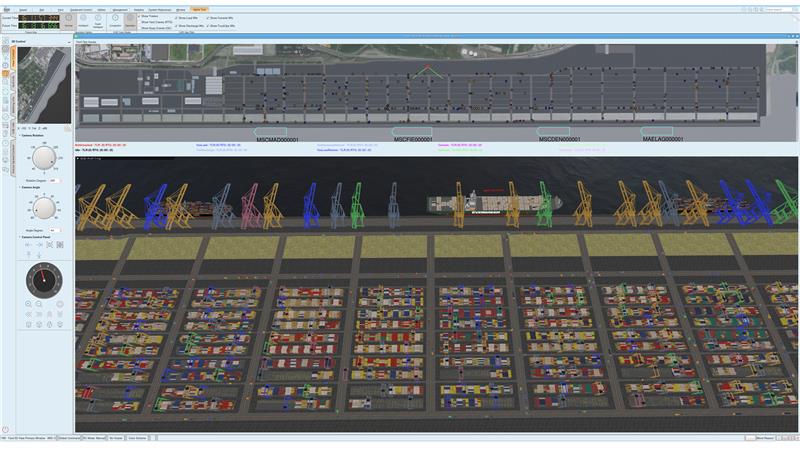

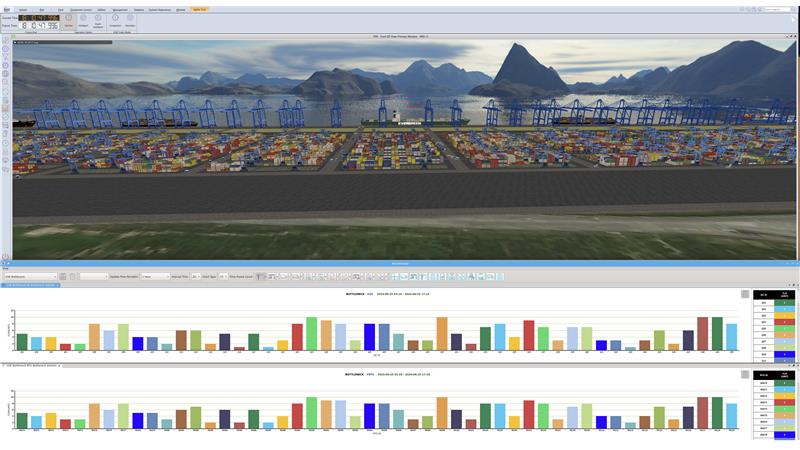

The latest product we have is called TOPX Intelligent 3D and we call it an intelligent digital twin, which is about replicating exactly as you see the terminal in a digital environment. Wherever each crane is, wherever each truck is, wherever each container is, you will see it as it is in the system.

It is intelligent in multiple ways. Firstly, it can perform predictive analytics, meaning that it can simulate future scenarios. Additionally and more importantly, it then can identify and solve problems in relation to these scenarios. It makes suggestions on how to make your terminal operations better and more efficient. Hence the name intelligence.

And what it is offering is really a new way of thinking about terminal operations.

Because with these predictive analytics, we are now trying to solve problems before they even occur. With this system it is going to be sitting on any type of terminal, and including any other TOS providers (that is not RBS).

We are very open to adding this optimization layer on top of all these different types of system infrastructures to bring benefit to the terminal. What we want to do is not replace anything at a terminal, not change any of their processes. We just want to add something on top to improve it and help them solve problems before they even occur.

What about your strategies? What sets RBS apart from your competition?

I think that comes down to two main things. Number one, especially in relation to the last question, is the very product-centric approach. We at RBS have been always dedicated to building the best product and incorporating all the technologies of the current time to build what we like to call a future-proof product. It is also the reason why many of our customers have been with us for quite some time, even more than 20 years.

Number two, it is about the people, our relationships and experience. So internally, we have people who have been working with us for more than 20 or 30 years now. On the external side, we also have great relationship with our customers.

One of our slogans is “Your success is our commitment”. It’s all about creating a partnership where we have win-win situations. It’s about putting things together. We want to bring success to everyone.

So that idea of relationship experience combined with our product-centric approach really sets us apart from many other competitors.

What are the key objectives of RBS in 2025, and what is your vision about the next five years?

In 2025, we are looking to roll out our new product, TOPX Intelligent 3D, across as many markets as possible. We have already seen strong interest, which makes this an exciting thing for us. We are also planning to enter the General Cargo and Ro-Ro markets by the end of the year.

In terms of our more medium to long-term approach (five to 10 years), we see new products, such as our TOPX Intelligent 3D, really taking off and taking over the global market.

This year has been largely focused on education and helping people understand this new approach. And I believe that over the next five years, we’ll see it spread widely. Because it’s designed to sit on top of any TOS, so it has the potential to become very prevalent.

Regarding other market trends, we also see many inland terminals coming up, as several governments have heavily invested in that type of facilities. As a result, we see our TOS being implemented in many greenfield terminals.

Overall, we expect an even greater dependence on technologies like the TOS, the optimization of TOPX Intelligent 3D, and eventually fully automated terminals.