Digital supply chains require information that is instantly accessible in order for the chain to hold together. Smart containers will supply that link, offering stakeholders greater visibility of the end-to-end logistics connections. Hanane Becha, Todd Frazier, Michael Schroeder, and Jaco Voorspuij explain what is needed to achieve smart supply chains and how to get there.

Smart Container solutions empower supply chain stakeholders to enhance their operations using reliable physical data to provide door-to-door visibility and AI-based predictive services for deriving predictive event determination, as well as visibility into the status and environmental condition of the container and its goods at any point along the route of the container.

The UN/CEFACT Smart Container project is of importance in the development of global international multi-modal standards to support the future of global trade. The project employed a step-by-step methodology to reach common understanding of smart containers and to deliver a smart container data model by defining the data elements, the code lists, and the messaging standards that can be used in the future development of APIs for communication with smart containers.

The Smart Container solutions

A “smart container” is considered to be a marine shipping container, which is fitted with a permanently installed smart monitoring device. However, for other modes of transport, such as air or road, a Unit Load Device (ULD) is also considered a container, which may be fitted with an attached monitoring device that would convert it into a smart container.

In a related sense, a “smart device” has a set of sensors embedded within the container, enabling it to measure real-time information such as identifying location, door opening and closing, vibrations, temperature, humidity, and any measured physical parameters of the surrounding environment of the asset. The smart device has a communication capability, which enables it to send out the measured data to a collection centre. These tracking and monitoring devices can also be used to equip other types of assets such as rail wagons and truck trailers. Extra remote sensors could also be added or paired with the main smart device to address the specific needs of a given cargo consignment.

When trip plan and settings are used to parametrise the smart container solution, smart containers can differentiate business-as-usual conditions during the journey versus out-of-bounds conditions when certain measures exceed the configured thresholds, alerting stakeholders to take action (Becha, 2020b). For example, the smart container solution can detect and alert the stakeholder if a door were opened in an unexpected location during a journey (Becha, 2019).

The United Nations Centre for Trade Facilitation and Electronic Business (UN/CEFACT) has now developed the needed data exchange standards to promote and simplify the deployment of Smart Container solutions. These have been described and published through its Transport and Logistics Domain Smart Container Project, which began in October 2017, with all initial deliverables completed in October 2020.

This project aimed to promote the usage of smart containers in multi-modal transport and has defined the deliverables required for integrating smart container data into the different industry processes of stakeholders throughout the end-to-end supply chain (see Voorspuij & Becha, 2020; chapter 5).

Adoption of global multimodal data exchange standards guarantees operational interoperability. With new and emerging technologies being tested and implemented in today’s challenging supply chain environment, these standards are more necessary than ever. There are many benefits to adoption of standardisation in the usage of smart containers.

Smart container data exchange standards enable stakeholders in the logistics chain to reap the maximum benefits from smart container solutions, while enabling them to share data and associated costs, increases the ability to collaborate, which in turn increases efficiency, reduces development and deployment costs and cuts time to market. Furthermore, there are potential risks associated with developing and implementing solutions that do not conform to global standards. Proprietary non-standardised solutions impede interoperability of solutions leading to costly and time-consuming integration causing a user organisation not to implement all solutions that would benefit them and may result in vendor lock-in.

An official UN/CEFACT White Paper completed in December 2018 defines the smart container solution ecosystem and the value of this service for each player (e.g., the actors and the various potential use cases for this technology). This document was re-published by the United Nations Economic Commission for Europe (UNECE, 2019).

Subsequently, the Smart Container Business Requirements Specifications (BRS) was developed and published in September 2019. This is an official global UN/CEFACT deliverable (UN/CEFACT, 2019), that explains the value proposition of different smart container use cases in detail, with the focus on data exchanges, values, and formats.

The BRS document clearly identifies that the more information a smart container service provider receives about the planned trip plan and the desired physical parameters values, the more value can be obtained from the smart container investment (e.g. targeted alerts instead of simply periodic measurements).

Thus BRS ensures that the various ecosystem actors share a common understanding of smart container benefits by presenting various use cases. It also details the smart container data elements. Defining the data elements that smart containers can generate accelerates integration and the use of smart container data on different platforms for the enhancement of operations. In addition, utilising standard smart container data enables open communications channels between supply chain actors.

Concurrent with the development of the BRS was the task to define the data elements that would specify these processes. Each new project of the UN/CEFACT domain builds on its Core Component Library (CCL) or the appropriate subset of contextualised data elements, such as the Multi-Modal Transport Reference Data Model (MMT). The CCL brings together the data exchange requirements of international multimodal transport processes including related trade, insurance, customs and other regulatory documentary requirements based on the integration of trade facilitation and e-Business best practices.

The UN/CEFACT CCL data model is extensible and can evolve to meet changing needs of buy/ship/pay process stakeholders. Data elements to accommodate use cases as identified in the BRS (UN/CEFACT, 2019) and their associated semantic definitions have now been implemented in the UN/CEFACT CCL and the MMT.

The MMT includes transport booking, transport ordering and freight invoicing processes, together with the actual transportation and the required border clearance processes related data elements. Stakeholders can choose from and reuse data elements, as well as enrich the global Reference Data Models (e.g. MMT) and the CCL as part of the UN/CEFACT standards development processes. These data elements create contextualised, technology-independent notification message structures.

In this data modelling process, items added to the CCL and the MMT include:

- Sensor related data-elements and classes

- Geographical information data-elements and classes

- A total of approximately 120 additions to the CCL with six changes to existing entities (related to geographical objects)

- Linking to MMT entities like Consignment and Transport Equipment

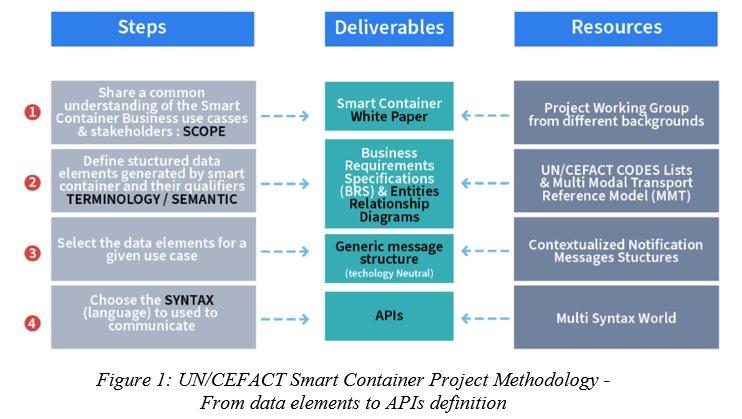

The methodology of the UN/CEFACT Smart Container Project, is based on four steps (Figure 1):

Identify stakeholders and the Smart Container services as provided in the BRS document.

Derive data elements to be exchanged by smart container solutions identified in the use cases (outputs and inputs of the services).

Select a subset of data to define a contextualised message structure to meet the requirements of a given use case. This message structure is independent from the technology that will be used to communicate the data.

Define a specific syntax-based information exchange using a chosen technology, which may result in API definitions or EDI message definitions based on standardised data elements.

Smart container code lists

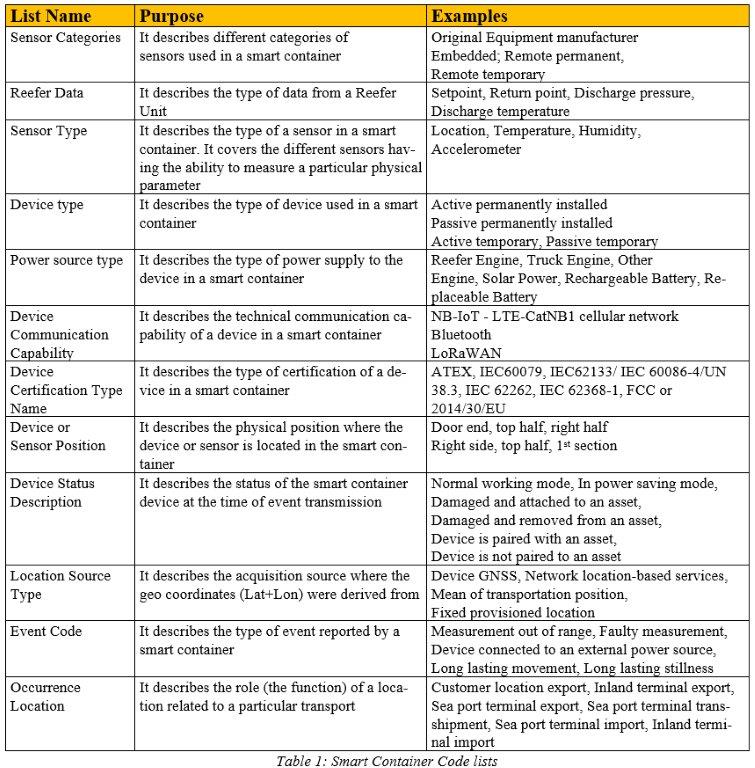

Step 3 of the process was finished in October 2020 with the completion of the Codes Lists and Messaging structures within the MMT, which concluded all the expected deliverables of the Smart Container Project. Eleven new code lists (e.g., defined codes, names and descriptions) were created to align the entries to specific data elements to complement the UN/CEFACT smart container data model. The table below records these types of code lists, their purposes and provides a few examples.

The following is a screenshot of the code list detailing the different sensors that can be embedded in the smart container device.

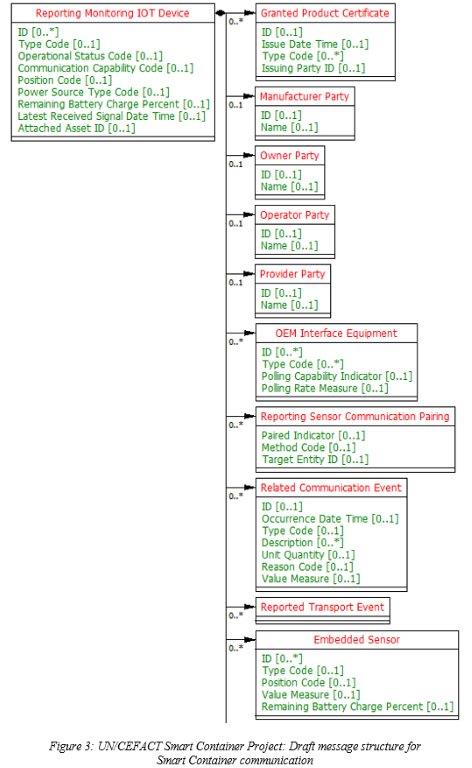

An example of the Messaging structure is provided below in Figure. 3

Next Steps

UN/CEFACT, in concert with other open standardisation organisations, will continue to develop and maintain standards for smart containers to ensure these will support the business requirements of stakeholders now and in the future.

At this stage, the smart container team has delivered the expected deliverables per the project proposal that was supported by the governments of France, Italy, Australia and the United States. The deliverables as presented above include the White Paper for decision makers, BRS, a concrete data model for dry and reefer containers based on well-established standards and various code lists that complement this data model. Many presentations and publications were produced to promote the adoption for the smart containers in general and standards-based solutions using these project deliverables.

A future Smart Container 2.0 update project to update the current data model (if required) with deliverable of an API catalogue for smart containers may be forthcoming. The UN/CEFACT is currently continuing work on Application Programming Interfaces’ (APIs) standardisation methodology, which will enable the development of a smart container API catalogue that can be the source code-based interface specification enabling software components (services) to communicate with each other.

Beyond the promotion and standards adoption, the team is now reaching out to early adopters. These early adopters include IoT providers and relevant organisations such as the DCSA, SMDG, and IATA to receive their input based on their review of the project deliverables. The team will continually maintain the standard code lists with the relevant organisations and ensure the relevancy of the data model.

This paper can be considered as a call for review and participation to maintain the new smart container related code lists.

Conclusion

The UN/CEFACT Smart Container project developed multi-modal open communications standards that can facilitate a state-of-the-art solution in providing and exposing services. Any stakeholder may orchestrate and enrich these services to meet their business process needs. The availability and exposition of these services can boost the digital transformation of the transportation and logistics industry, fuelling innovation in new applications and services. Smart containers will revolutionise the capture and timely reporting of data throughout the supply chains. Such containers are an essential building block to meet the emerging requirements for end-to-end supply chains (e.g., Voorspuij & Becha, 2020; Lind et al, 2020ab). As leading carriers adopt smart container solutions, they gain valuable data that can be shared with all authorised supply chain stakeholders.

DCSA is one example exhibiting that industry is adopting the UN/CEFACT smart container standards already: DCSA has defined the IoT connectivity standards in support of smart containers and other IoT enabled objects, which will accelerate further adoption of this technology.

Many concepts and initiatives have also emerged taking into account the smart container data and services. The maritime industry is taking advantage of emerging technologies and concepts including digital twin that enables to “digitally represent and simulate objects and events prior to decision making” including smart container. Digital data streams built upon standardised data sharing provide opportunities for real-time representation and simulation of authentic situations.

All initiatives using smart containers will be more successful when based on standards. The collaborative and joint efforts to support the improvement of the maritime sector by engaging an ever-larger community of people from research and practice also resulted in a textbook on “Maritime Informatics” covering all the emerging concepts that are transforming maritime-based supply chains.

Note. The opinions expressed herein are the authors’; they are not necessarily those of their employers or organisations in which they are active.

Acknowledgement

The authors would like to thank the Management, Secretariat and other experts of UN/CEFACT, in particular, Sue Probert, Lance Thompson, David Roff, and the other Smart Container Project Experts for their input, participation, guidance and feedback in developing this project.

About the Authors

Hanane Becha is currently the DCSA IoT program Project lead. She is also the UN/CEFACT Vice Chair for Transport and Logistics. Hanane received a Ph.D. and an M.Sc. in Computer Sciences from the University of Ottawa, Canada.

Hanane Becha is currently the DCSA IoT program Project lead. She is also the UN/CEFACT Vice Chair for Transport and Logistics. Hanane received a Ph.D. and an M.Sc. in Computer Sciences from the University of Ottawa, Canada.

Todd Frazier is Strategic Project Lead in the U.S. Regulatory Compliance group and is the FedEx Express Accredited Representative to the International Air Transport Association (IATA). He is also Chairman of the Cargo Services Conference, the cargo standards formulation body of IATA and is active in UN/CEFACT projects.

Todd Frazier is Strategic Project Lead in the U.S. Regulatory Compliance group and is the FedEx Express Accredited Representative to the International Air Transport Association (IATA). He is also Chairman of the Cargo Services Conference, the cargo standards formulation body of IATA and is active in UN/CEFACT projects.

Michael Schröder is Project Manager eSolutions at Hapag-Lloyd and contributes with his expertise in various standardisation organisations such as UN/CEFACT, DCSA and SMDG.

Michael Schröder is Project Manager eSolutions at Hapag-Lloyd and contributes with his expertise in various standardisation organisations such as UN/CEFACT, DCSA and SMDG.

Jaco Voorspuij is responsible for Industry Engagement Transport & Logistics at GS1, and has worked developing global data standards with various standardisation organisations (e.g. GS1, CEN, UN/CEFACT) and is co-chair of the International Taskforce Port Call Optimization.

Jaco Voorspuij is responsible for Industry Engagement Transport & Logistics at GS1, and has worked developing global data standards with various standardisation organisations (e.g. GS1, CEN, UN/CEFACT) and is co-chair of the International Taskforce Port Call Optimization.